FLOW.CONTROL for the new PRIMO swimming pool cover

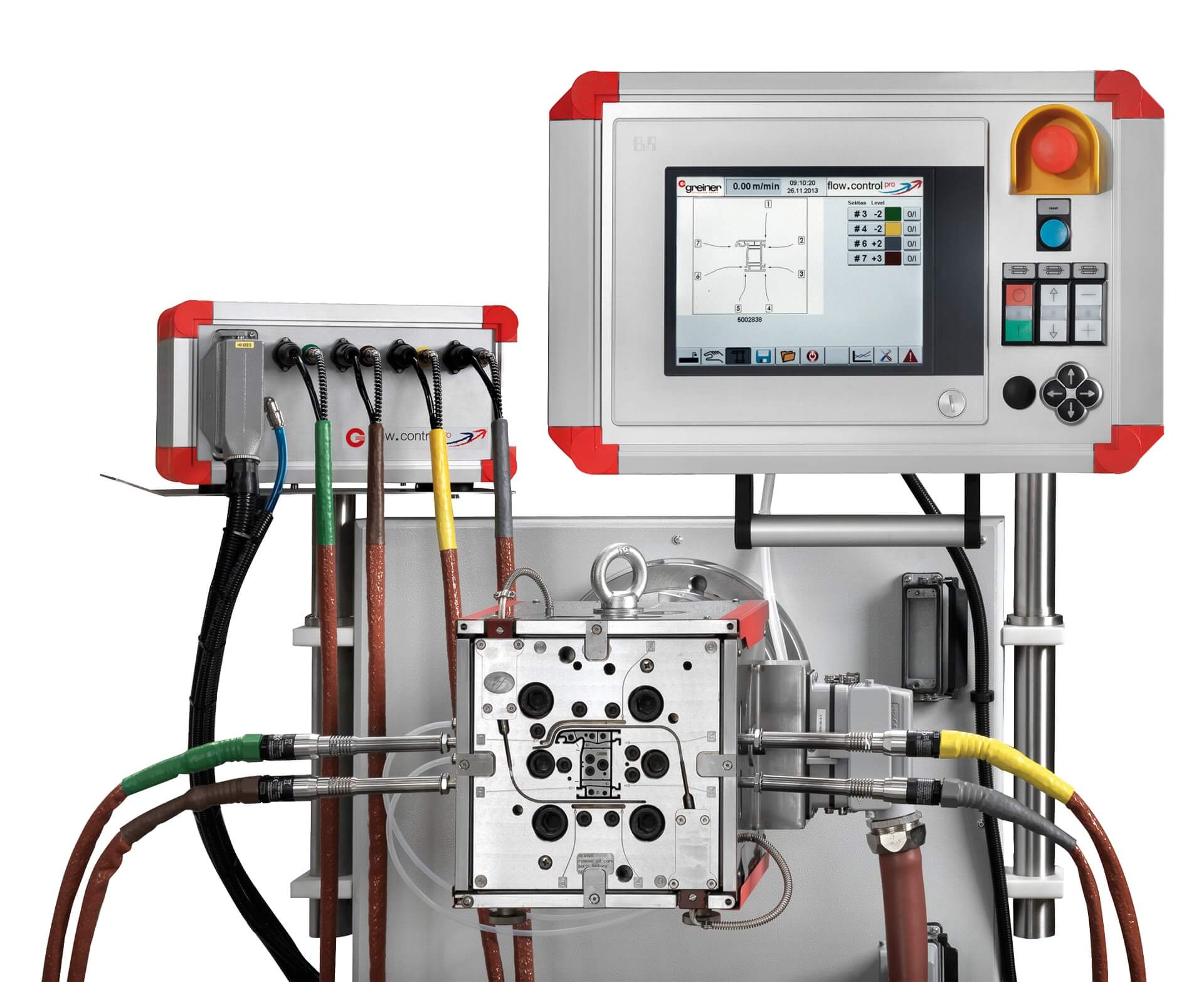

FLOW.CONTROL provides precise functional dimensions and reduces input material in extrusion.

With FLOW.CONTROL, an innovation of the Exelliq Group, the profile extrusion process can be improved long term. Melt flow control allows individual profile sections to be decelerated or accelerated selectively with cold or hot air. That guarantees functional dimensions while providing considerable material savings. The melt flow reacts within minutes, usability is improved, and all settings can be reproduced. The additional control possibility increases line flexibility, and the reaction/intervention time in the event of environmental variations is reduced significantly. FLOW.CONTROL guarantees the highest process reliability, shortens start-up times, reduces scrap rates and makes production cycles longer. FLOW.CONTROL can be retrofitted for the majority of our dies.

FLOW.CONTROL for the new PRIMO swimming pool cover made of PVC and polycarbonate

The current development of PRIMO, a system for pool covers made of PVC and polycarbonate, imposes high functional and design requirements. For the rolling cover profiles to interweave smoothly, they must provide exact dimensional accuracy, especially with respect to hooks. By controlling the relevant profile sections, FLOW.CONTROL ensures that such necessary functional dimensions are followed.

PRIMO develops, manufactures and sells extruded plastic profiles for products of many industries such as construction, electronics, energy, furniture, shipping, medical technology, lighting, offshore, power plants, transportation, household appliances, windows and doors, and many more.

"With certain profiles, FLOW.CONTROL is indispensable for us to be able to meet the high requirements with regard to the geometries of the profiles. What is more, FLOW.CONTROL drives total profile costs down through considerable material savings, a lower reject volume, and shortened start-up times. FLOW.CONTROL is an outstanding system to monitor the extrusion process. This allows us to ensure efficient production for our customers. Given the notable savings achieved, PRIMO will continue to invest in further FLOW.CONTROL systems next year. Thanks to our material savings, we can also offer environmentally friendly and resource-saving solutions”, says Harald Möllenkamp, operations manager at PRIMO.

PRIMO Group

PRIMO is an international group of companies employing over 700 people at 13 production sites in 8 countries. For over 50 years, PRIMO has been a development partner for plastic profiles and system solutions in numerous sectors such as windows and doors, construction, air conditioning and refrigeration technology, electrical engineering, household appliances and transportation. The PRIMO Group is headquartered in Copenhagen.

From consulting to the finished product, PRIMO is a valuable partner in every phase. The company's business is based on an understanding of customer needs, and the ability to deliver innovative, reliable, high-quality extruded plastic profiles. The range of services they offer is completed by prototyping, machining, tooling, additional materials, and the manufacturing of raw plastics. Production sites and sales organisations are located in all Scandinavian countries, Germany, Poland, Russia and China.

Exelliq Group

Exelliq Group is the world’s leading supplier of extrusion lines, tooling and turnkey plants for profile extrusion. The core competency of the Exelliq Group lies in its know-how of the profile extrusion process – development, design, manufacture and process optimisation of toolings and extrusion lines. The service portfolio ranges from formulation development to extrusion lines and from toolings to the engineering of complete production plants. At 10 production and service locations in Europe, the United States and Asia, all-in-one solutions are provided for any requirements profile manufacturers around the globe should have. With 6 tuning department centres and 15 permanently available extrusion lines as well as one of the largest development centres in the entire industry, Exelliq offers its customers a complete range of services to develop customised solutions for a greater competitive advantage in profile extrusion.