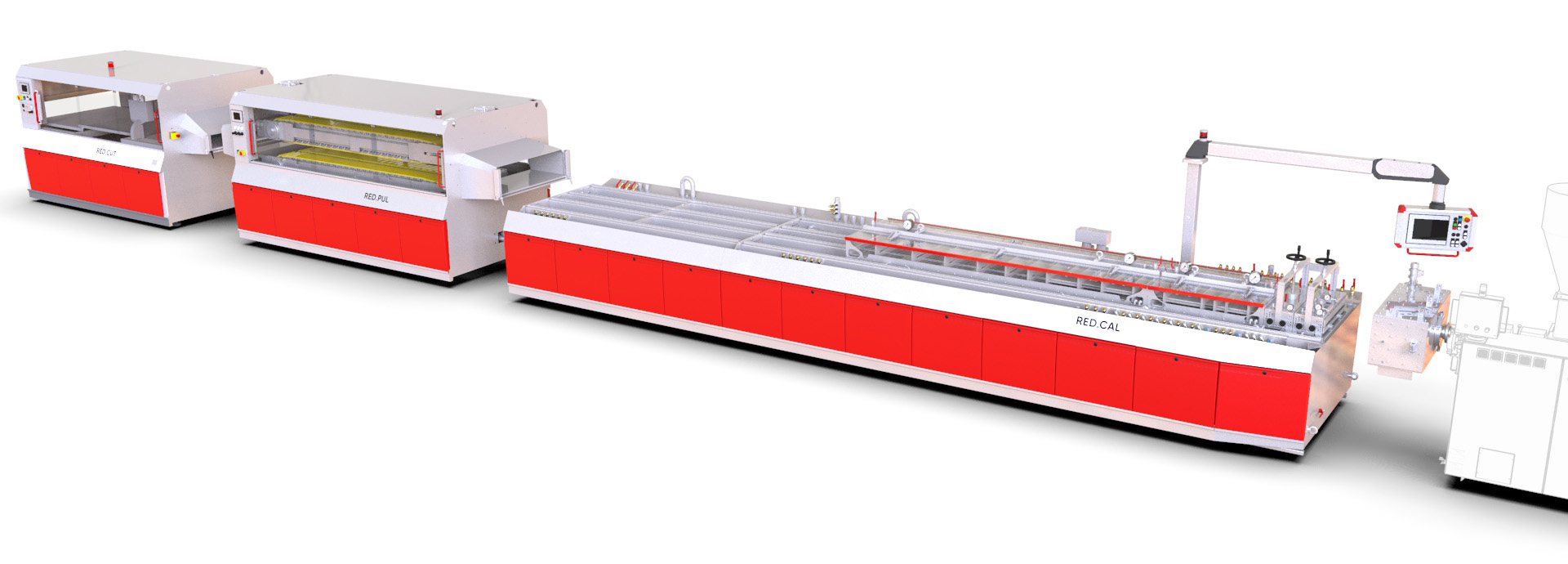

RED.LINE wide – the wide extrusion line

Your ideal partner for XL extrusion profiles

XXL profile cutter and saw for cutting precision

Stable XXL caterpillar-haul-off for safe profile withdrawal

also available as RED.LINE and RED.LINE basic

Calibration table for XXL profiles with a width of up to 1,000 mm

optional G4 operating panel

The giant among the tooling systems

Both the RED.LINE and RED.LINE basic machine systems come in the wide version (up to 1,000 mm wide). The massive RED.LINE wide shines with a high level of process reliability due to tried-and-tested components and with utmost flexibility thanks to the equipment module system. The ergonomic positioning of the operating panel facilitates handling. Manual lateral adjustment allows for precise calibration alignment.

- Wide calibration table for up to 1,000 mm large profiles

- Twin strand is a possibility due to modular construction

- Precise alignment due to height, side and tilt adjustment

- All components integrated into the machine’s body

XXL.TOOLING

The giant among the tooling systems.

From broad window sills to generously-sized panels and massive embankments, XXL.TOOLING was specially developed to extrude even the largest profiles with process reliability and precision. For applications with a width of up to 1,000 mm, this stainless steel giant keeps things in shape.

RED.CAL wide

This giant stemming from the RED.CAL calibration table product range enables process-reliable withdrawal of large profiles with dimensions of up to 1,000 mm. Despite its mighty dimensions, the height, side and tilt of RED.CAL wide can be adjusted and set up to fit the extrusion process perfectly. And not only the calibration table but the entire RED.LINE wide has been designed also so that all components are integrated and not a single moving part sticks out from the machine’s body.

RED.PUL wide haul-off

The extra-wide haul-off of RED.PUL wide allows for large profiles to be withdrawn reliably – even if the wall thickness or inner wall is thin. This is ensured by the 900 mm wide pads, which have a generous contact length of 2,300 mm, thereby reducing the surface pressure on the profile down to a minimum.

RED.CUT wide

The widest cutter from Exelliq is equipped with the tried-and-true technology of the RED.CUT product portfolio to ensure that the large profiles are cleanly cut at the end of the extrusion process.

- NEW: RED.CUT disk for PVC foam profiles up to 625 mm wide and 45 mm high (hollow chamber profiles up to 25 mm)

- 2 variants of the disc cutter: cutting either across or along the extrusion direction

- High-precision and chipless cutting - without noise, without dust