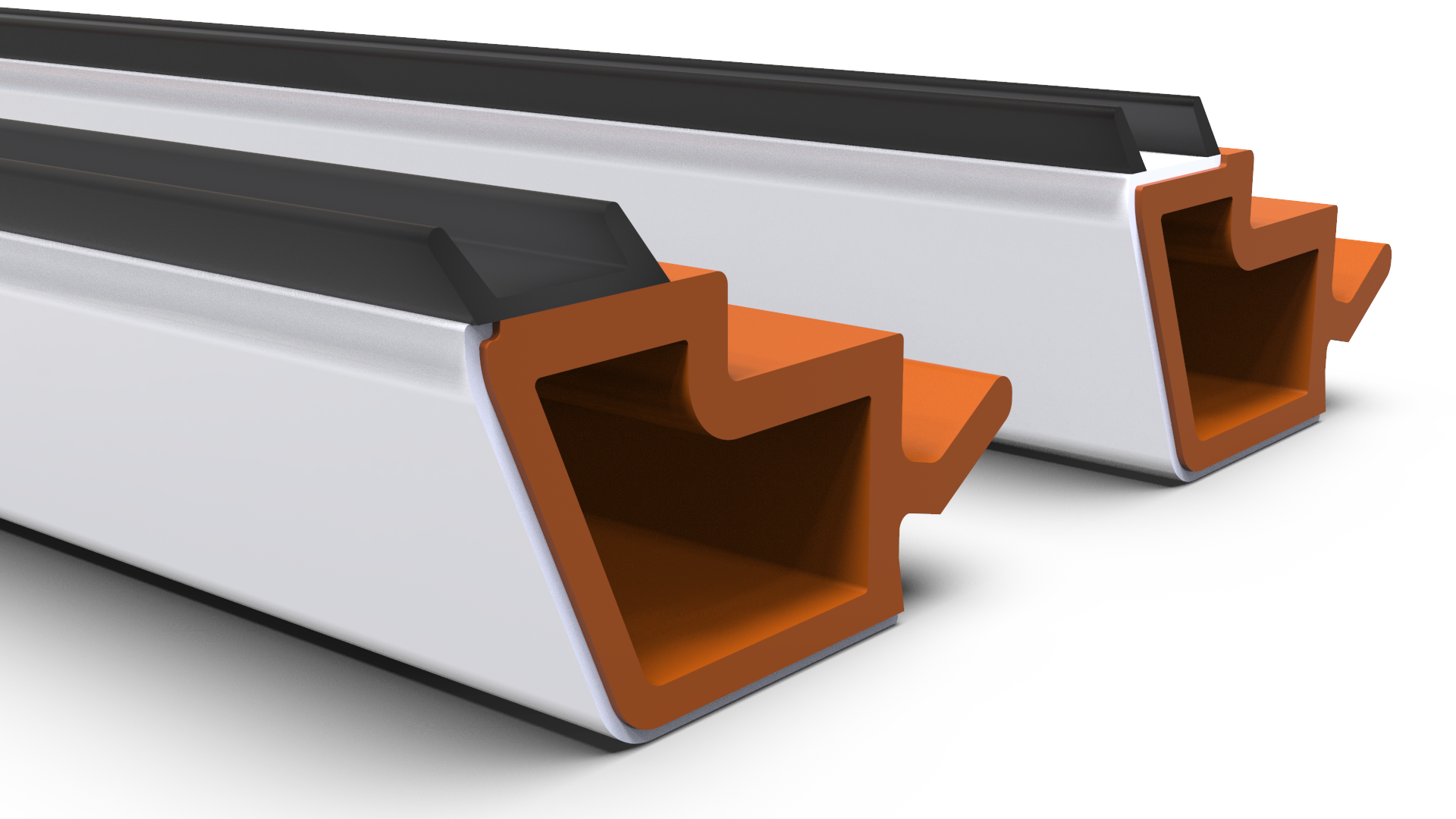

Producing glazing beads becomes cheaper and more sustainable - thanks to co-extrusion

Exelliq's proven co-extrusion technology, which brings recycled plastic into the production process, is now available for glazing bead tooling. Glazing bead profiles have the advantage that they are not welded. Therefore, the layer thicknesses in the visible area, where the cost-intensive PVC virgin material is used, can be kept particularly thin. This makes it possible to use the cheaper regrind for up to 85 % of the necessary material. This reduces manufacturing costs and protects the environment in terms of a circular economy and the reuse of existing plastic. Possible subsidies for increasing the proportion of recycled material round off the package.